Rail

Rail Depot Workplace Organisation Improvement

Rail Depot Workplace Organisation Improvement

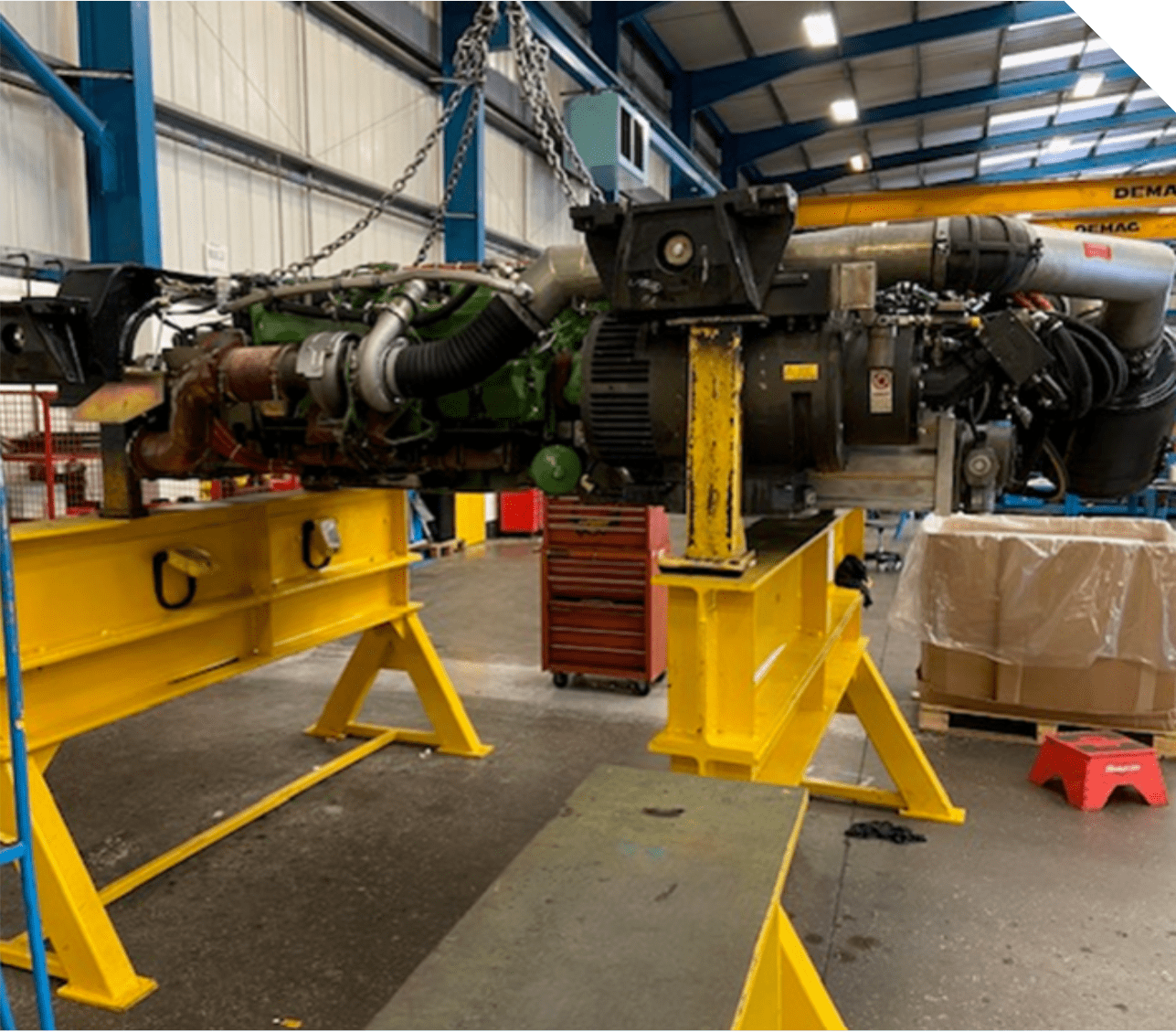

Working with the UK & Ireland’s largest rolling stock servicing organisation, Develop Consulting were asked to support a major workplace organisation project at its busiest East Midlands based site.

After a number of years of highly successful operations, the depot required a workplace organisation refresh. Over the years the technical content of the maintenance activities had developed and therefore the need to review all tooling and equipment versus point of use would improve the effectiveness of the examination teams.

Develop Consulting’s scope of activity was to initially assess the current operational status, engage with the teams as to current tooling and equipment issues / opportunities and then develop and implement a workplace organisation. improvement plan, based on 5S principles

Results

- Reduction in time and effort locating the required tools, equipment and parts, now located next to the point of use.

- Improved workshop environment, resulting in rapid identification of spills or contamination, reducing the risk of slips, trips & falls.

- Elimination of the need for personal tools by providing the standard tools for the examination process at the point of use.

- Placement of heavy items in multiple locations reducing manual handling risks of moving the parts.

- Improved waste segregation process through the provision of work area based and standardised waste bins.

- Clearly visible, visual standards in place around the work site.

- Start and end of shift based 5S audits to confirm all adhering to the required standard for examination work completion.

- Improved working environment.

- Workplace organisation model created for planned wider roll-out programme.

Observations

Operating across 24 hours a day and 7 days a week, with a significant element of activity overnight, the depot had well defined activity plans to achieve the required examination and service schedules for various train operating companies. To support the required workplace improvements, Developing Consulting led a number of activities, including:

- Conducting a significant number of process observation activities, across all of the operational shift periods, engaging with the technicians to understand the issues and frustrations with the current workplace.

- Working alongside the Shift / Exam Leads & the shift-based Team Leaders to gain insights into their day-to-day challenges for the exam teams.

- Defining ownership zones across the whole depot, with agreed key shift-based leaders made responsible for those zones.

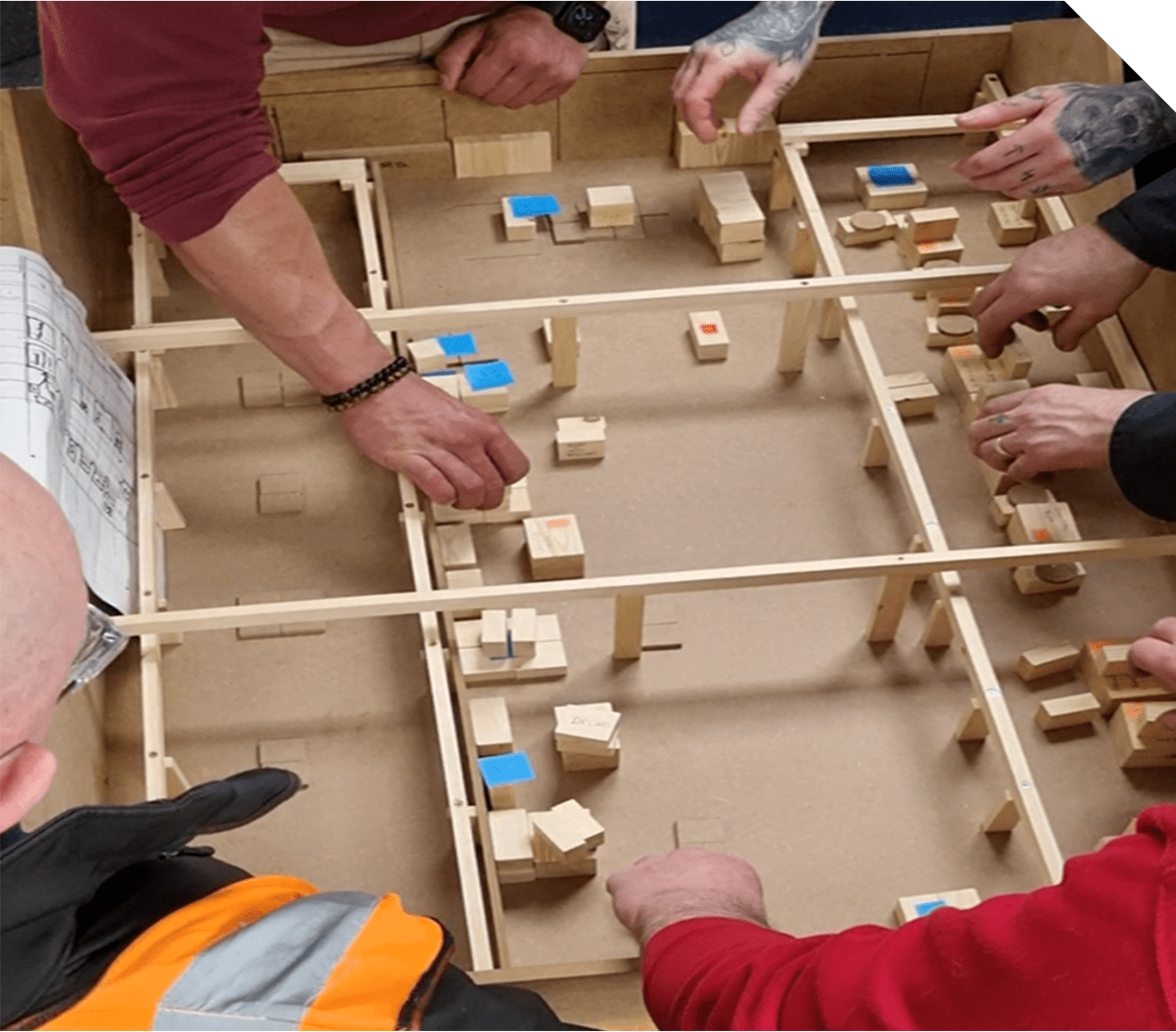

- Developing a detailed 5S roll-out plan, with an agreed pilot zone to set the required improved standard.

Objectives

Develop Consulting’s scope of activity was to initially assess the current operational status, engage with the teams as to current tooling and equipment issues / opportunities, and then develop and implement a workplace organisation improvement plan, based on 5S principles.

Actions

As a result of the observations and planning, a number of improvements were delivered:

- A site-wide road based floor repair & painting programme implemented.

- Road-by-road full 5S programme rolled out – Sort to Sustain.

- A full set of revised tooling and equipment lists implemented, alongside replacement shadow boards, charging stations and material storage.

- A full waste management review and updated waste stations for all areas.

- Fully refreshed and updated spill management kits and stations across all operational areas.

- A detailed start and end of shift 5S check for all areas with a defined issue escalation process.

- A defined leadership routine to support and manage the sustainment of the new standard.

- A defined 5S implementation standard to enable an accelerated UK-wide 5S programme.