Rail

Site Layout Consolidation

Site Layout Consolidation

In 2024 Develop Consulting supported Wabtec LH to review, consolidate and improve their overall site and process layout.

Wabtec is a global provider of equipment, systems & digital solutions in freight rail, transit and mining.

Based near Burton-on-Trent, Wabtec LH is the largest overhaul and repair centre for undercarriage train engines in the UK. They service clients from the UK, Ireland, Germany, Spain and Italy, with a turnover of circa £40M p.a.

Results

- 3,900 m2 of factory floor space released and/or re-purposed.

- Outsourced process repatriated, saving c.£500k per annum

- Building process density increased (better usage) whilst improving individual workspace and product & material flows.

- Improved workforce morale through direct engagement and improved working and welfare conditions.

- H&S conditions improved with flooring and lighting repairs/upgrades.

- Positive feedback from key customer visits.

About the Programme

Wabtec LH operates from an industrial estate in South Staffordshire, and consists of a number of different business units, under a single ownership, which was then bought out by Wabtec in 2013.

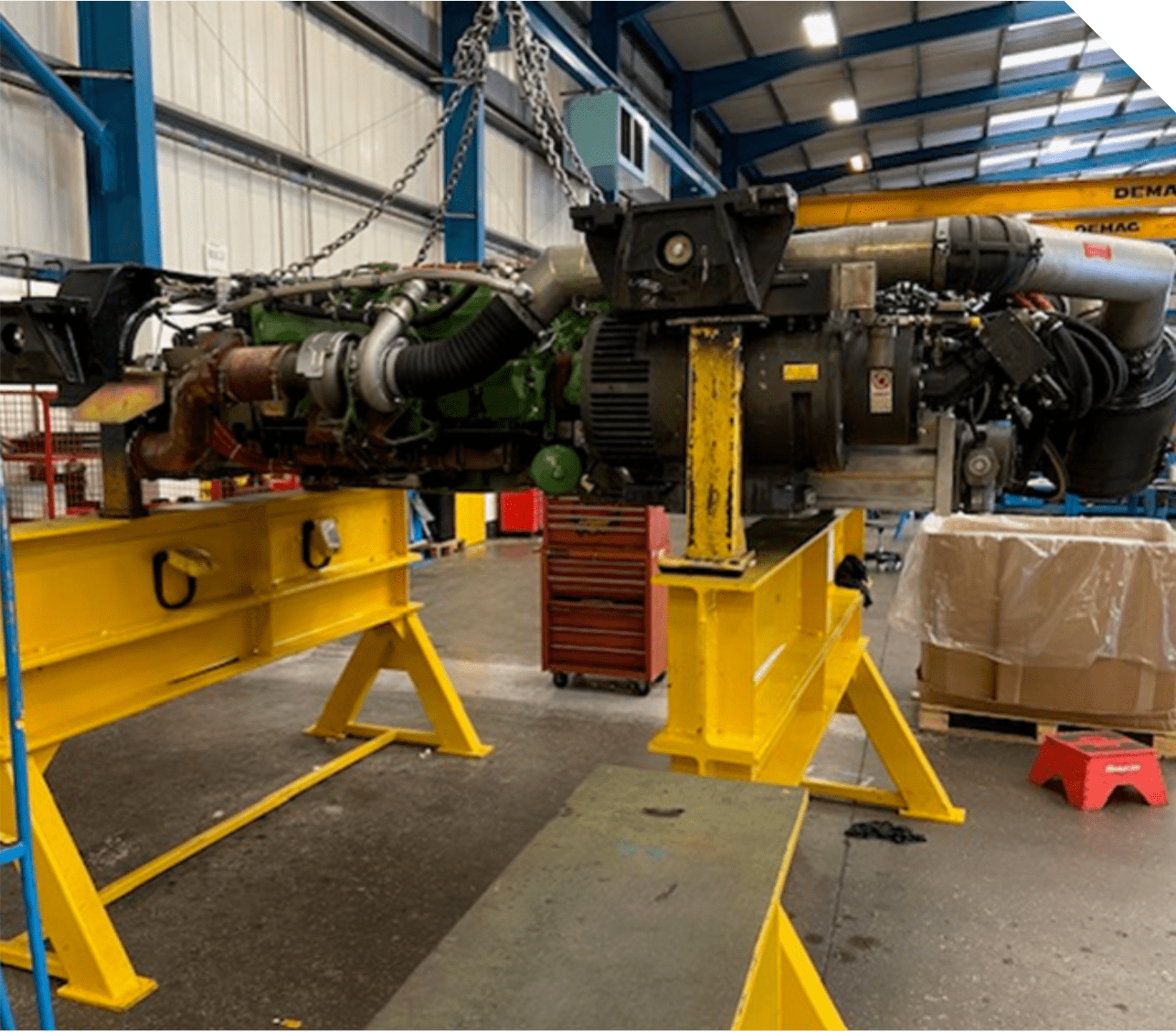

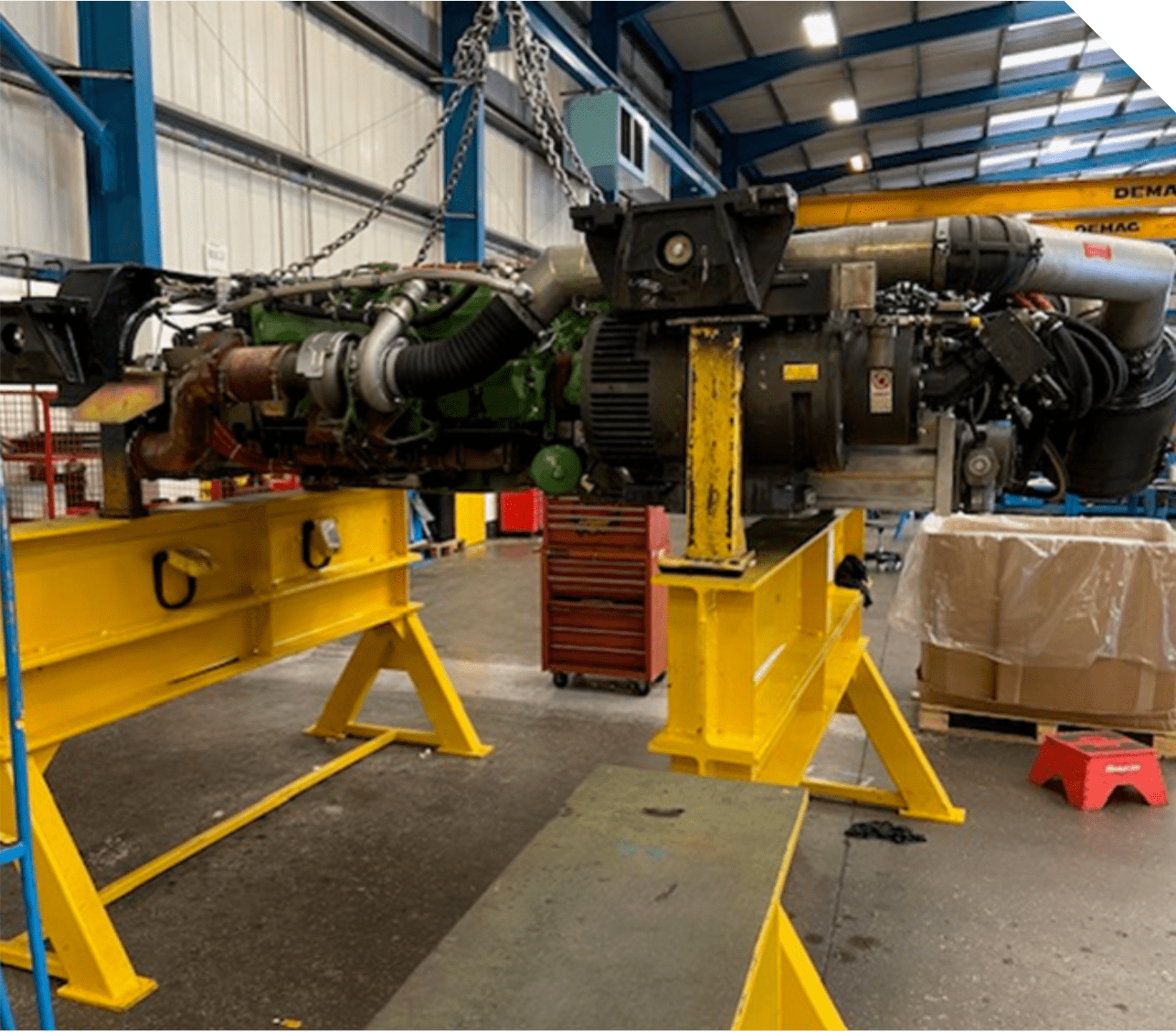

The end-to-end servicing and overhaul of rail locomotive power units and the supporting engineering processes, were spread out over the site, occupying eight different industrial workshop buildings.

Material flows and WIP status were difficult to manage, with inefficient internal logistics and sub-optimal labour efficiencies, due to the dispersed site layout.

Some of the 20~50+ year-old buildings were also in need of maintenance and upgrade, to bring them up to modern industrial standards.

Develop Consulting were tasked to review the whole site layout, infrastructure and end-to-end process flow, and then design a new consolidated site layout to make better use of the existing space, and release two of the six buildings for future work opportunities.

Working closely with the local management team, we were also asked to plan and manage the execution of the site transformation.

Solutions

A full review of the site, buildings, equipment and processes was undertaken to understand and then propose what could and should be relocated. This also included the review and removal of redundant equipment and processes in order to release additional factory floor space.

A project master schedule was created and reviewed weekly by the site management team, with further detailed ‘action’ plans to manage the detail sequencing of each area move & relocation.

Specialist flooring and lighting contractors were brought in, and managed, to provide a more modern uplift to a number of the newly created work and canteen areas.

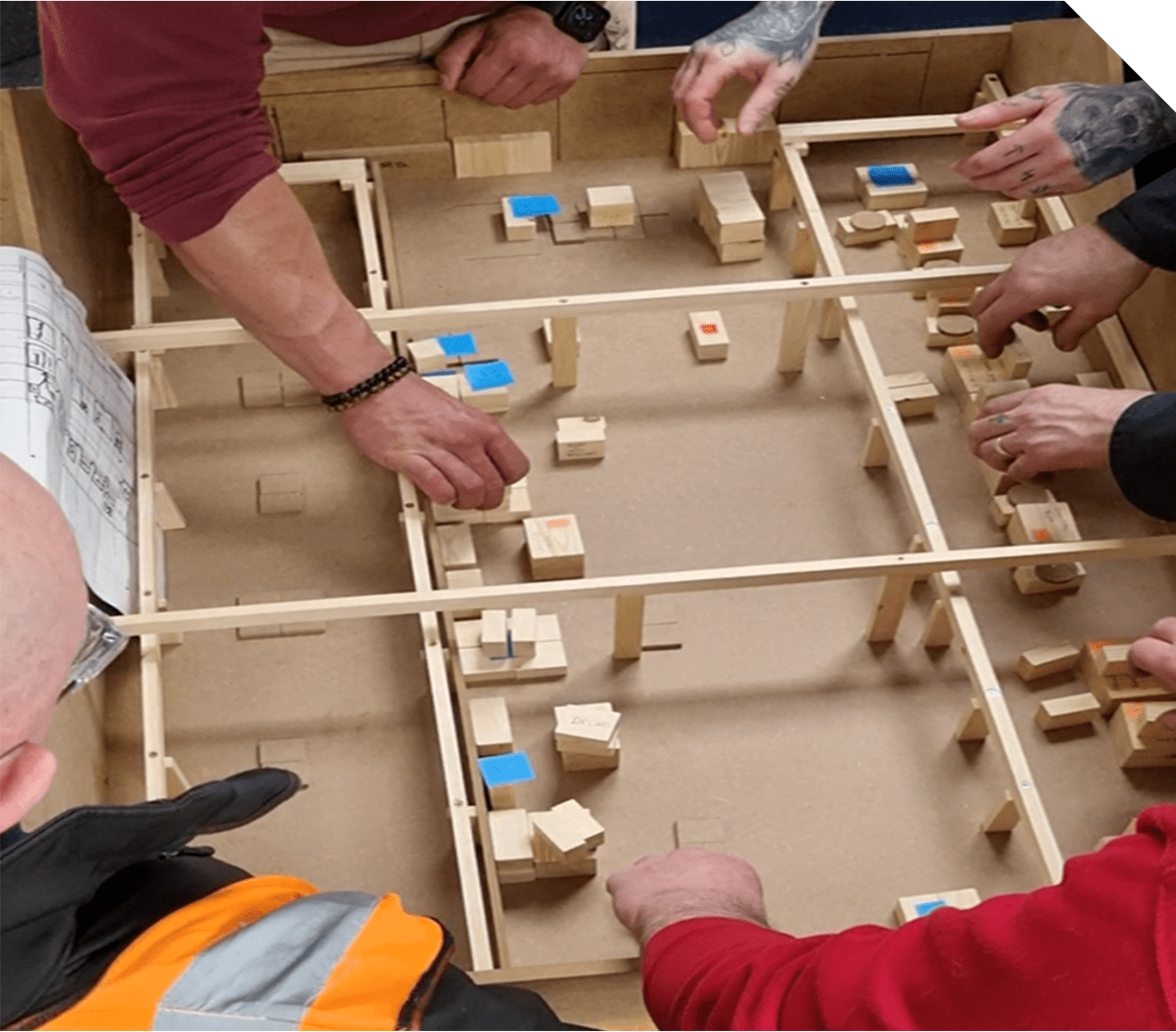

New process layouts were developed very much with the local shopfloor teams, ensuring lots of good ideas and improvements were integrated into the ‘moves’, as well as buy-in from those teams.

In the early phase of the project, an opportunity came about to repatriate a previously outsourced overhaul process. Some of the new space was re-allocated, and an additional sub-project was managed by Develop-consulting to relocate this process and its associated equipment.