Rail

Engineering Office: Process Improvement

Engineering Office: Process Improvement

Our client is a Global Rail Designer & Manufacturer, located in the UK with multiple offices across Europe for Design and Engineering support.

Due to the size of the organisation and growth being built on a number of legacy companies and processes, the control and grip to manage Engineering had been diluted and deadlines were consistently being missed.

Results

- Improved output by 57% from the Engineering department – Design, Change Mgt, Mods & Documentation

- Improved communication and stakeholder management – Production, procurement & Senior Mgt

- identified savings of over £20m through contractor reduction

Objectives

- To achieve deadlines to support the wider business (OTIF)

- To remove waste from systems and processes & Improve cycle times

- Introduce visual management

- Create a Continuous Improvement culture

- Create a clear policy deployment, KPIs, SLAs

- Empowerment within teams

Actions

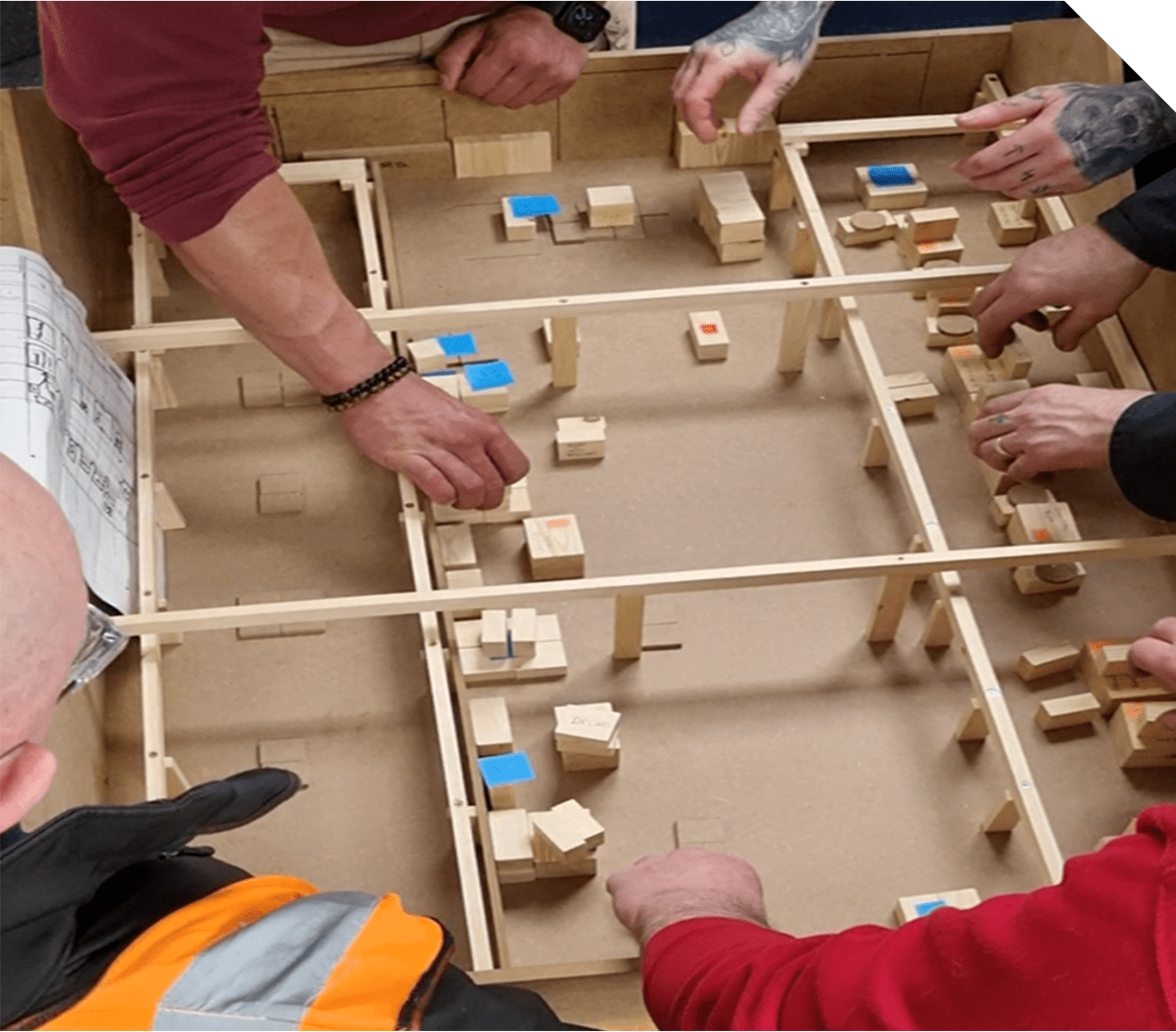

We started by agreeing the functional responsibilities structure and completing capacity vs demand modelling for each function i.e. Driver systems, Passenger systems, etc. and then created a structure to deploy targets and measure daily output through visual management & short interval control (SIC).

We then re-designed the meeting cadence and planning to achieve tasks and deadlines by Engineer or Team.

We also purged the system for ECRs (Engineering Change Requests) and Approvals documentation.