Rail

Non-Conformance Process Improvement

Non-Conformance Process Improvement

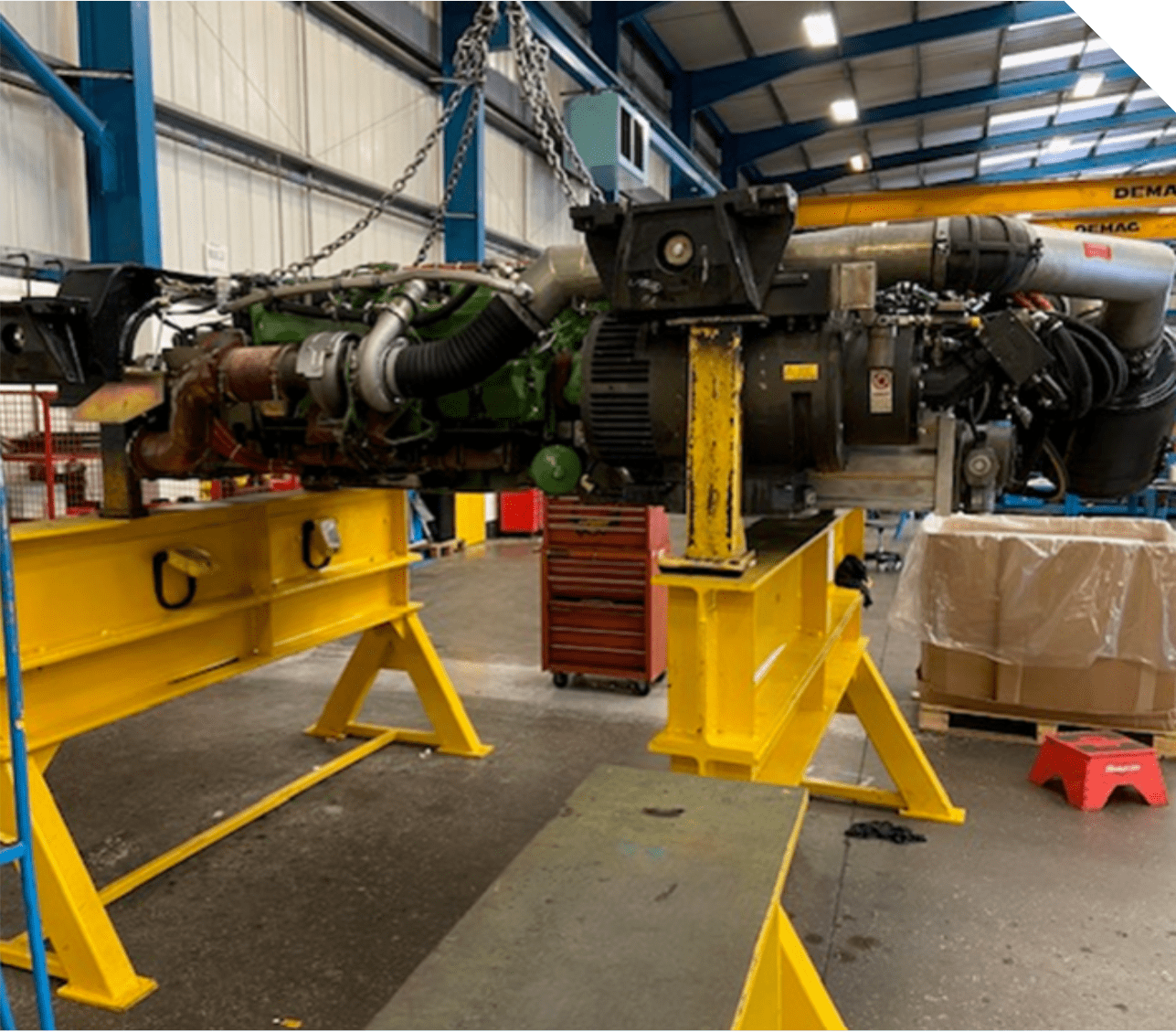

Working with one of the UK’s largest heavy engineering and manufacturing companies, Develop Consulting were engaged to support a significant reduction in the number of occurrences and impact caused to the business due to non-conforming parts and materials.

Our client was seeking to continue to manufacture a number of key projects, and the occurrences and management of non-conforming parts was impacting on that ability to manufacture on-time, resulting in a number of key commodity groups and their associated supply chains negatively impacting output.

Develop Consulting were asked to assist in improving the control and processing of the non-conforming parts, to reduce the impact on the supply chain and continued parts supply, alongside supporting the operational teams in root cause analysis to eliminate the occurrences of non-conformity.

Results

- An 64% reduction in NC part volume

- Release of £10.5m of NC parts back into the supply chain for the required rectification back to good part status

- Implemented short interval control of NC parts, through multi functional team reviews at the process level

- Implementation of a revised NC part process, reducing delays and enabling effective and visible processing of the NC part in less that 16 hours from occurrence to deposition

- Developed and approved process standards alongside required training and skills matrices

- Implementation of a revised organisational structure, creating clear ownership of NC parts, root cause analysis and reporting of performance

- Implemented daily and weekly dashboard KPI’s enabling rapid action & control to ensure effective processing of NC parts

- An overall ROI on the investment of over 20:1

Observations

The manufacturing process was achieving its planned volume but with significant ongoing impact from the supply of parts, therefore increasing the risk and impact on maintaining the required output. A major cause of that impact related directly to the volume of non-conforming parts, and the processing of those parts back through the supply chain to then become available for use.

Objectives

We were tasked to assist in improving the control and processing of the non-conforming parts, to reduce the impact on the supply chain and continued parts supply, alongside supporting the operational teams in root cause analysis to eliminate the occurrences of non-conformity.

Actions

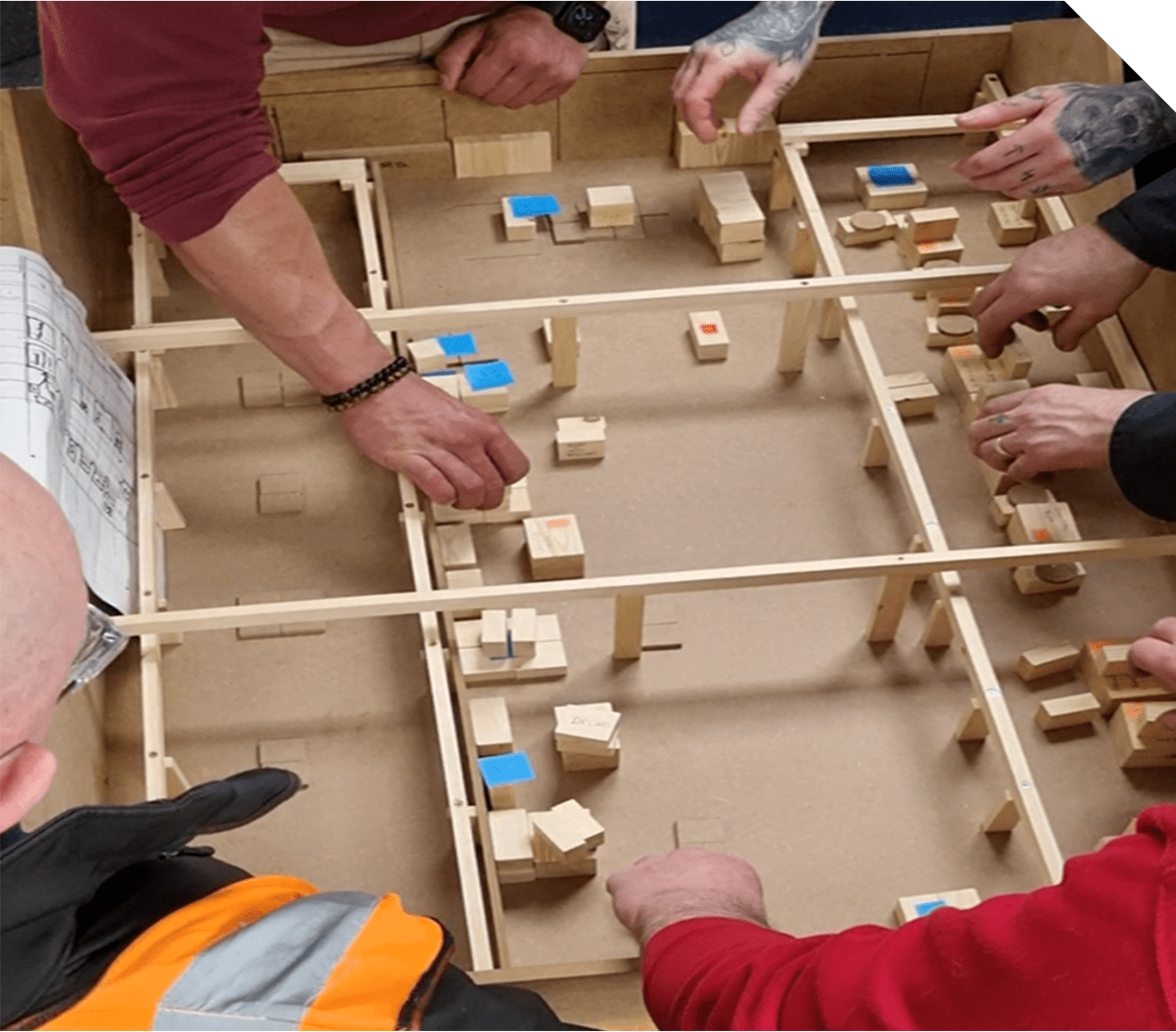

Develop Consulting, alongside a core team from the client, developed a centralised Project Management Office approach, with a detailed improvement plan.

Initial shop-floor based process reviews enabled a series of improvement activities aligned to a revised non-conforming parts management and control process (fully SAP system driven).

Critical to ensuring the required process improvement could be measured and reviewed, Develop Consulting utilised the on site ERP system to generate key performance data, to create a set of management process performance dashboards.

Aligned to the required process control, a revised organisation structure was agreed and included in the improvement plan.

The updated Non-Conforming Parts (NCP) management and control process was developed and confirmed with the required client stakeholders. The process was then rolled out across the business, with fully supported training, how-to-guides and early-life process support.

A key part of the overall solution was the implementation of daily NCP reviews (individual project / manufacturing process based), led by the NCP core team, driving rapid understanding of the NCP issue, adherence to the NCP process and effective processing of the NC part back through the supply chain.

Develop Consulting analysed the NCP “in-delay” parts, understanding the issues causing the delays, and drove solutions to those delays, releasing significant volume and value of parts back into the supply chain.

Daily and weekly KPI’s were implemented to ensure clear visibility of the process and rapid escalation of any blockages or significant manufacturing impact. This included a measure of non-conforming parts in delay, so that a set of specific actions & activities could happen to eliminate those delays.

The programme supported the operational teams to drive effective problem solving to eliminate the root causes of the non-conformances.