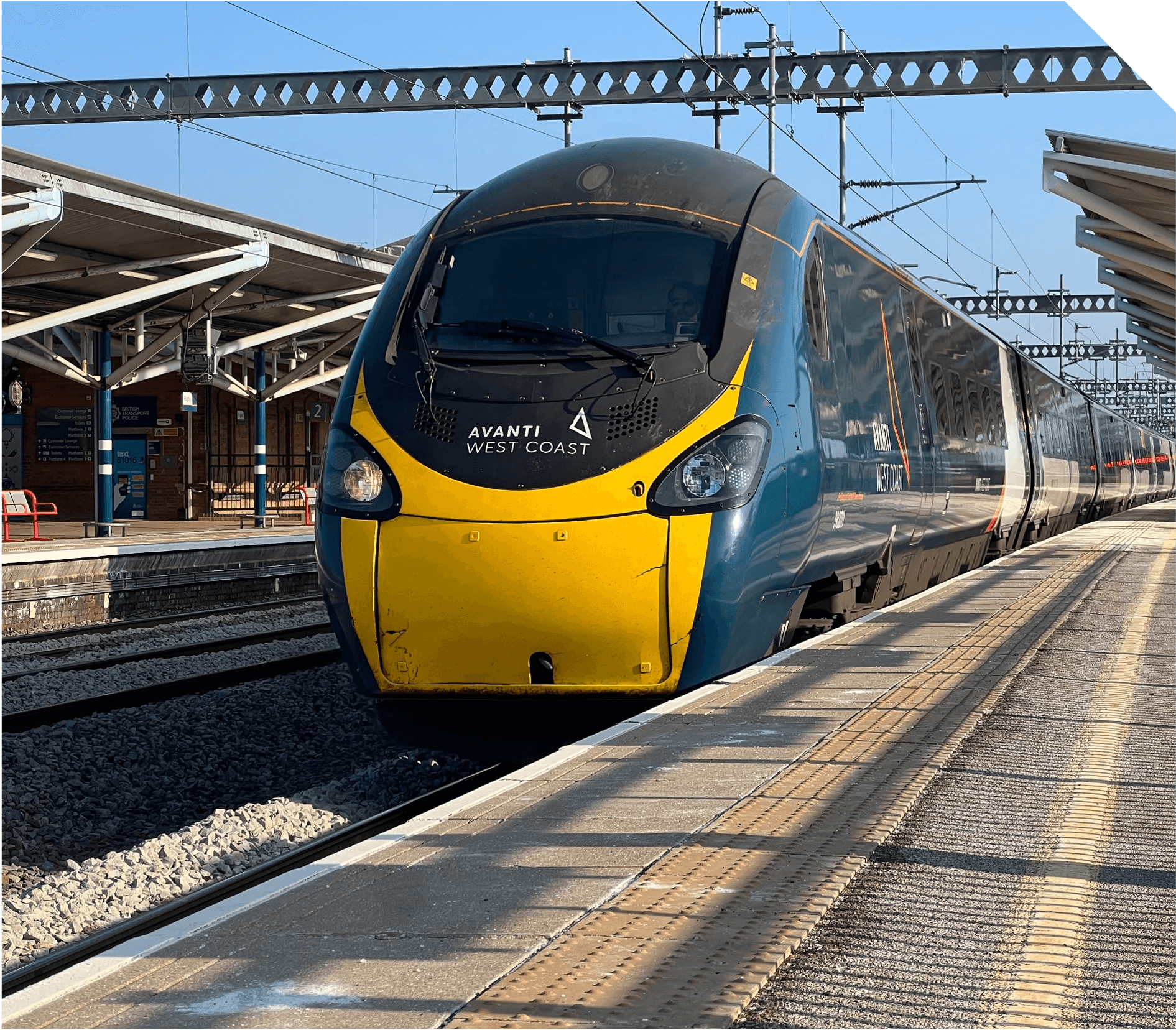

Rail

Process Optimisation

Process Optimisation

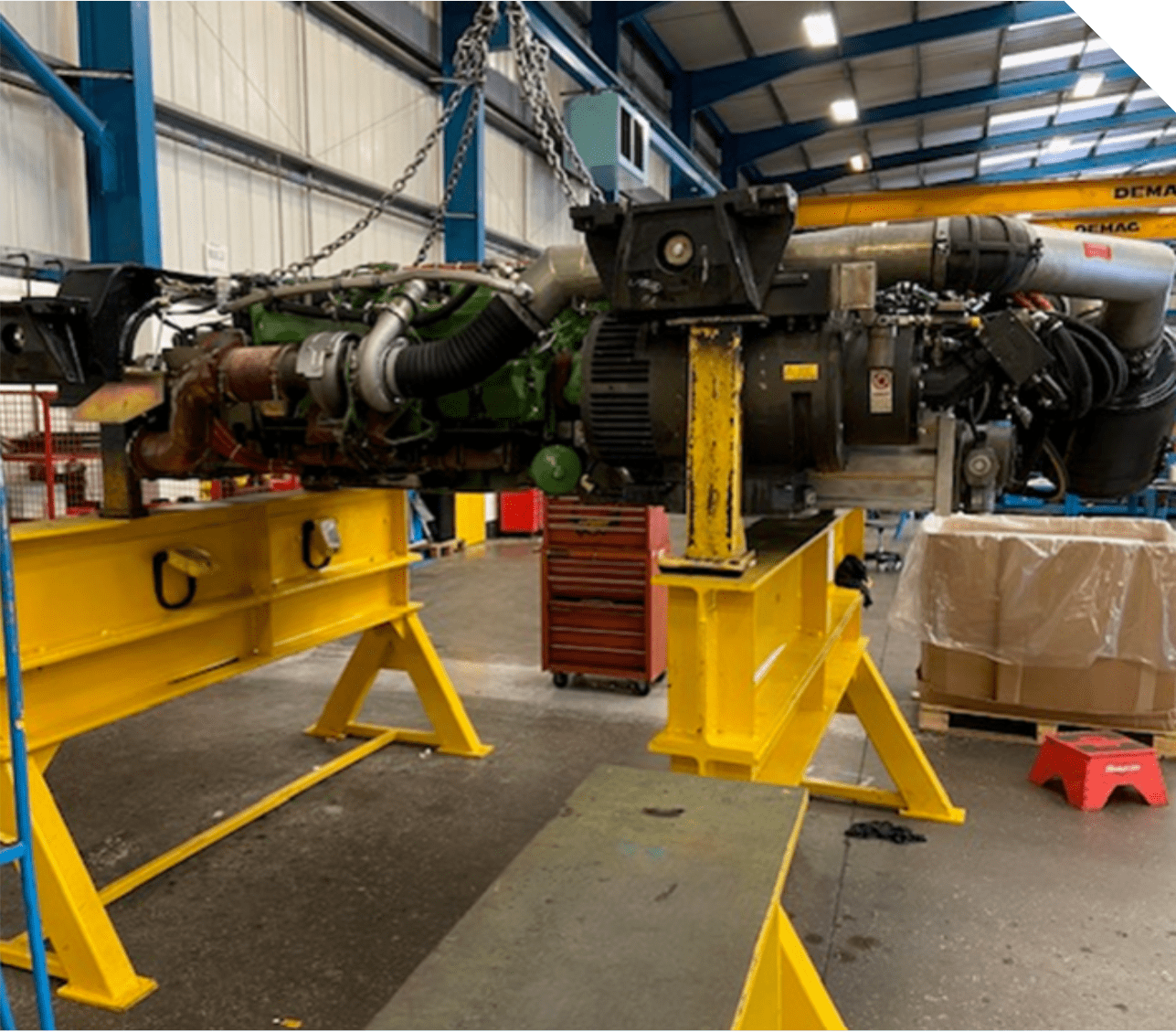

In 2023 Develop Consulting supported a global provider of equipment, systems & digital solutions in freight rail, transit and mining, to optimise their processes and layout to improve the feed of rail engine raft kits in to Assembly, in order to meet customer delivery contracts.

Results

- Capability to deliver the schedule using the same resource levels confirmed

- Capacity to deliver an additional 2.75 raft kits per week identified (additional £7.9M p.a)

- ROI of 43:1 (Develop Consulting cost + implementation cost)

Observations

Our client had a contractual obligation to “turn around” a fully serviced engine raft in 20 days, from door to door. At commencement of Develop Consulting’s support, they were only able to achieve a 28 day return.

Objectives

Non delivery to the schedule risked causing “holes in trains” or forcing the customers to extend the engine service hours under concession. Late deliveries were leading to penalty charges and a reduced annual turnover.

Through ‘Value Stream Analysis’ it was identified that the Cleaning process was the bottleneck for the site, and at current capability would be behind schedule by 2.9 raft kits per week, leading to a potential deficit of £8.3M in annual revenue.

Actions

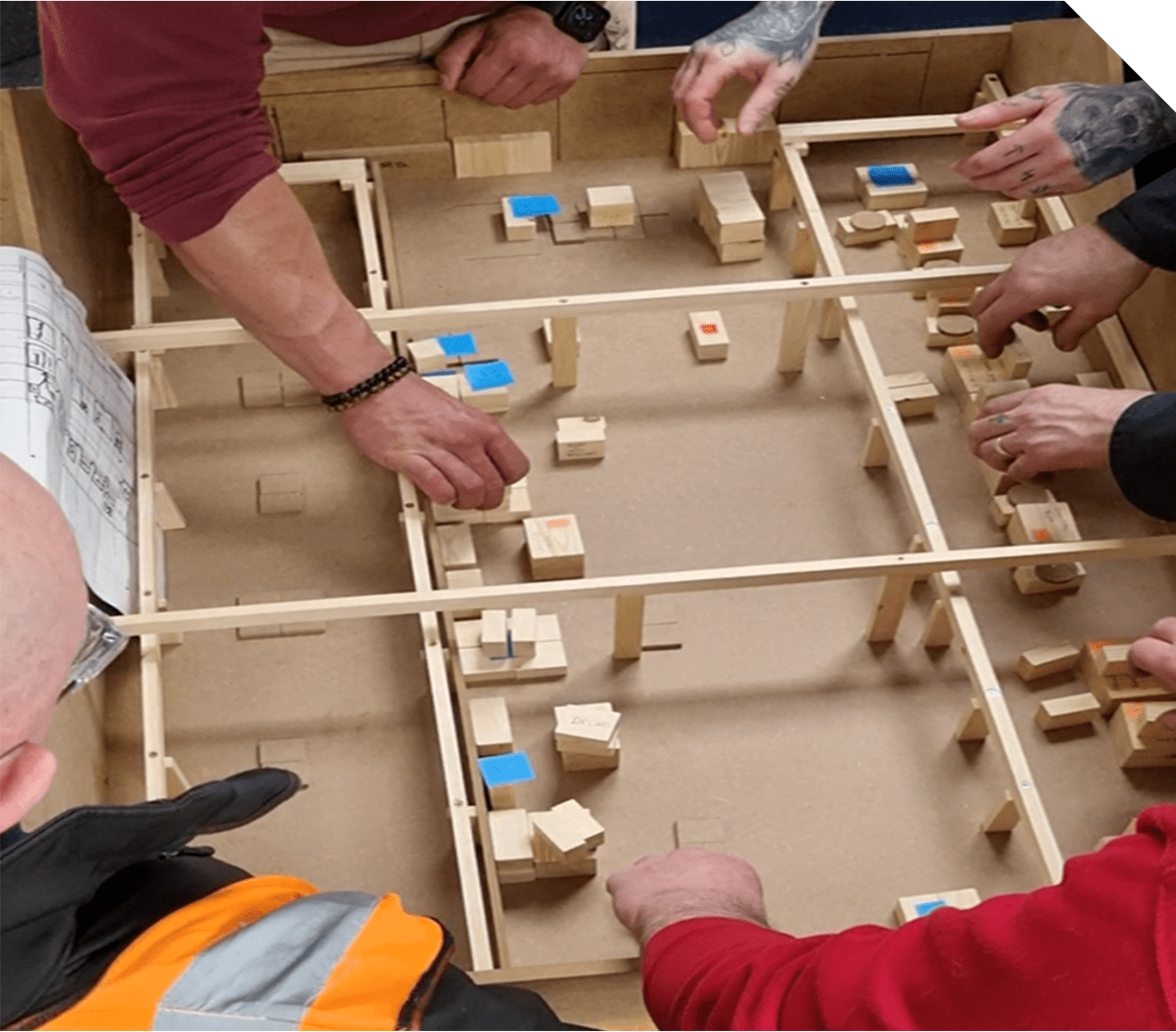

Having previously created a process map, Develop Consulting led a 5 day ‘3P’ (production, preparation, process) Kaizen workshop to identify the ideal future state.

Using a 3D model of the Strip & Clean facility and working with the components cleaning machine supplier, the Kaizen Team designed and analysed multiple options to change the process & equipment layout and chemical configuration of the cleaning machines. These options were measured against an agreed priority matrix and the best three options identified. These were then virtually simulated using the 3D model to identify potential snags, bottlenecks and WIP requirements.

The optimal layout and chemical set-up was agreed, and an implementation plan developed and executed. SOP’s were generated to support training of the new processes, before handing over to the Production Team.