Business Operations

Cadent Gas Planning Improvement Programme

Cadent Gas Planning Improvement Programme

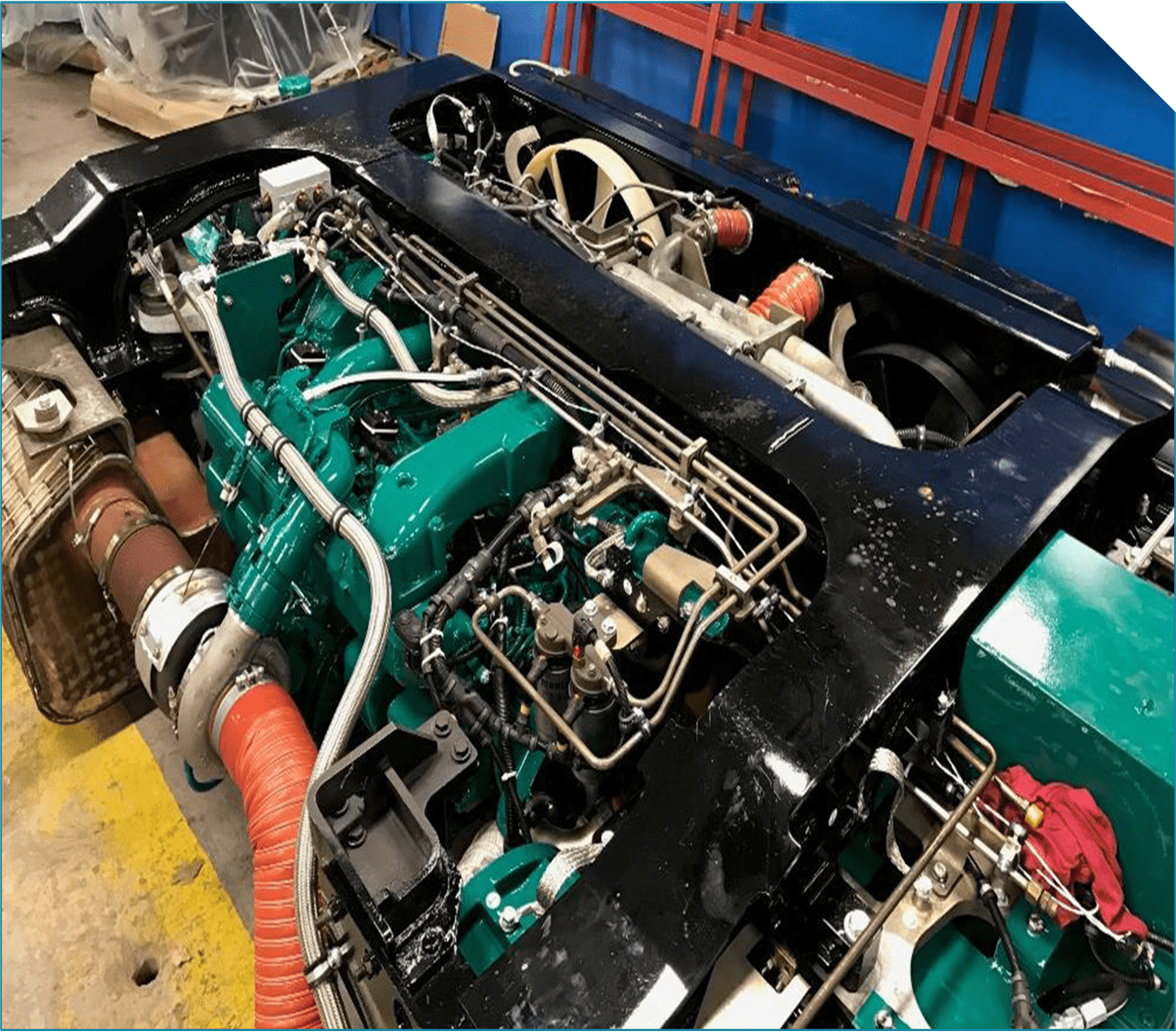

In 2021 and 2022, our team developed a new programme to assist Cadent Gas in servicing and maintaining 543 pre-heat radiators for the gas network.

Results

- A 60% reduction in overtime identified year on year giving an annual saving of £50k.

- The elimination of fatigue through the ability to flatten the workload over a 12 month period.

- A cost avoidance of £190k over a 3 year period through the elimination of external lifting and transportation within the West Midlands site

- A predicted ROI of 4.5 to 1 over a 3 year period.

About the programme

Cadent approached Develop Consulting to assist with a planning and improvement programme.

The client had recognised that there was a high level of fatigue which was being reported on the site within the teams based there, which was attributed to poor resource planning and management.

Because of this, the annual work plan was being compressed into a six-month period, instead of evenly throughout the year.

The client recognised that they did not have sufficient skills or experience within this department to create a structured planning tool to enable the work to be balanced across the working year.

In addition to this, Develop Consulting observed that Cadent hired heavy cranes and transportation to move assets within the West Midlands site, costing £80k+ a year due to their own site equipment not being capable of lifting the weights.

Objectives

Develop Consulting were asked to step in to assist in four areas of the business:

- Mechanical Workshop – carrying out welding, shot blasting and inspection activities

- Mechanical Delivery – managing lifting operations, site / asset

based removal and recommissioning and non-gaseous

mechanical works - Calibration Laboratory – serving gas detection equipment

- Portable Tools and Equipment, PAT testing, mechanical

and annual maintenance.

Actions

Through value stream mapping and visual management, our consultant was able to identify the key timescales within the processes and understand the rules that needed to be applied to a schedule.

These rules were built into a planning tool where they were overlaid with the de-commissioning dates to automatically generate an end-to-end plan showing when materials need to be ordered, surveys need to be carried out and then set targets for workshop to ensure the asset is ready for re-commissioning as agreed.

To support the understanding of resource requirements, a “Crib” was developed to record the ACTUAL time spent on all activities which fed into a resource calculator, giving the management team real data to identify manpower levels needed in the 4 departments. Investigated solutions for safe in house lifting and generated a business case to be offered to the Upper Management Team in order to obtain finance to purchase new equipment.