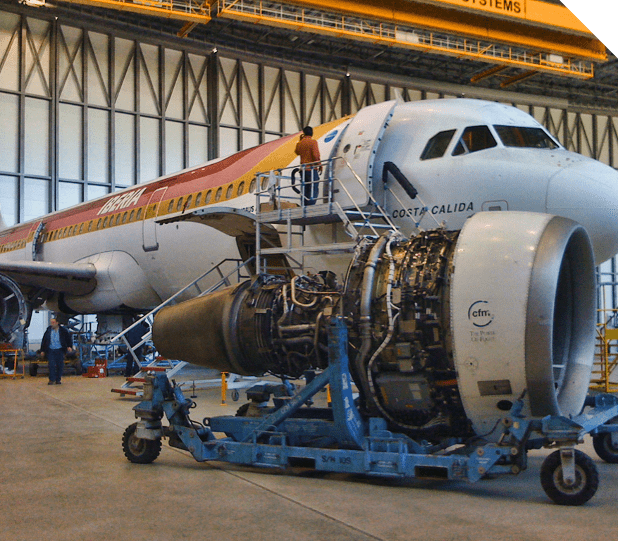

Aerospace

Aircraft Production Process

Aircraft Production Process

The client is positioned as one of the worlds leading and largest aircraft manufacturers, they have five spare part centres, 160 field sites and three fully fledged training centres globally.

They employ 56,000 people, producing a comprehensive range of commercial aircraft and being renowned for their efficiency, innovation, economy and safety. Manufacturing, production and sub assembly of parts for customer aircrafts are distributed by 16 sites in Europe, with final assembly in Toulouse, Hamburg and Tianjin. Our team were working within the Southern France site.

Results

3 days of lead time reduction

Inventory saving of 1 fuselage sets and 2 aircrafts, equals 36.7 million Euros

Observations

No standard work available

High waiting time due to unbalanced work

No controlled visual follow-up system in place

No structured system in place for line balancing

Duplication of work within the office processes

No structured communication between departments resulting in passing through of incorrect information

Objectives

Streamline the Final Assembly Line to cope with increased demand of work

Reducing Lead time for the concession process (office process). Currently this jeopardises the release of the aircraft for the ground test & test flight

Coaching & knowledge transfer to the local management team and Lean implementation group

Actions

INVESTIGATION

Creation of current state value stream map for the production process & concession process

FINAL ASSEMBLY LINE

Assignment of a pilot area

Work order study

Creation of Yamazumies

Creation of standard work for the assembly line

Implementation of 5S in the production area

Set –up of KPI’s for the production areas (SQCDP)

Implementation of a sustainable process confirmation system for all levels

Introduction of problem & countermeasure follow-up

Creation of andon system to raise concerns

CONCESSION PROCESS

Development of a new procedure for the concession process

Determination of Roles & Responsibilities for the involved departments

Creation standard documents for the concession registration

Creation of andon system to raise concerns

COACHING & KNOWLEDGE TRANSFER

On the job training of the local Lean implementation group during the entire project

Training of entire management, staff and teams in the Lean Tools