Airport Operators

Airport Busing Process Improvement

Airport Busing Process Improvement

Working with one of the UK’s fastest growing airports, Develop Consulting were asked to review the current busing operation in the context of a forecasted significant passenger throughput increase expected in the summer peak period.

Results

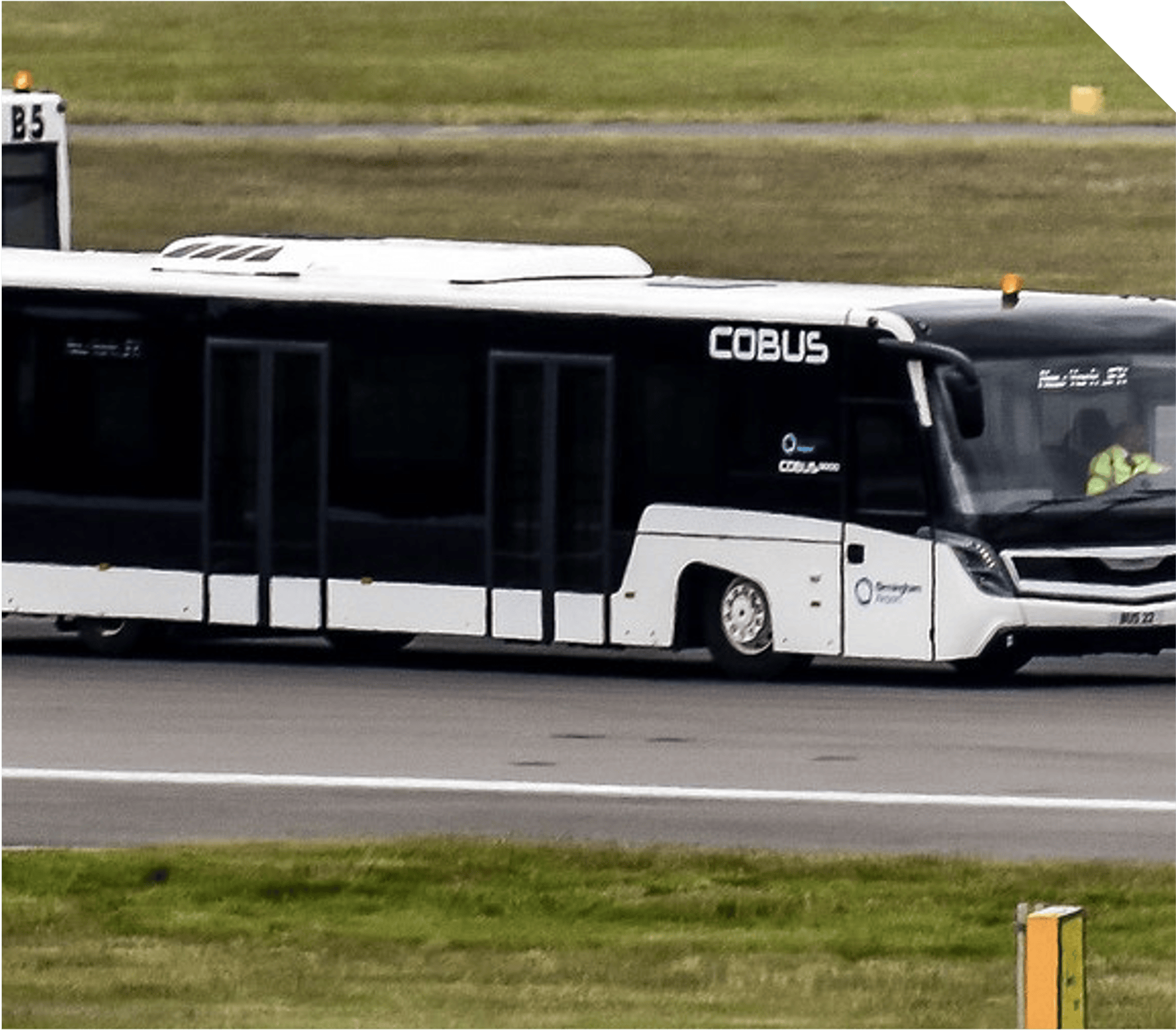

- A 12% volume increase in bus journeys achieved with no additional hours in January 2024 compared to January 2023

- Improved processes to ensure all movements achieve a minimum 10 minute arrival promise

- Zero delays attributed to the team

- Avoided the need to recruit 4 additional drivers for 2024/ 25 and a 60% reduction in overtime

- 10% improvement in daily resource utilisation

- Avoided any additional buses required to support 2024 / 25 forecasted demand

- Daily performance review in place in operations room – review yesterday, today and tomorrow, with agreed actions to resolve any issues / risks to performance

- Operational skills matrix implemented to drive additional training in readiness for summer demand

- Bus monitor board including detailed VOR information and visibility of bus usage across fleet to balance mileage

- Demand based Motor Transport SLA detailed to support varied demand across the operational year

- Detailed next six months improvement plan developed, reviewed and approved for delivery

- Volume and forecast analysis for peak 2024 periods

- An initial ROI on the investment of 2:1 and roadmap to

achieve more

Observations

Recent organisational changes gave the terminal operations team the opportunity to understand fully the current busing operation, it’s capability to support the forecasted increase in passenger volumes and time to prepare for that expected increase.

Objectives

Develop Consulting’s scope of activity was to initially assess the current operational status, implement rapid basic standards, and then to define the continuous improvement plan for the 6 months leading up to the summer peak to ensure the operation was “match fit”.

Actions

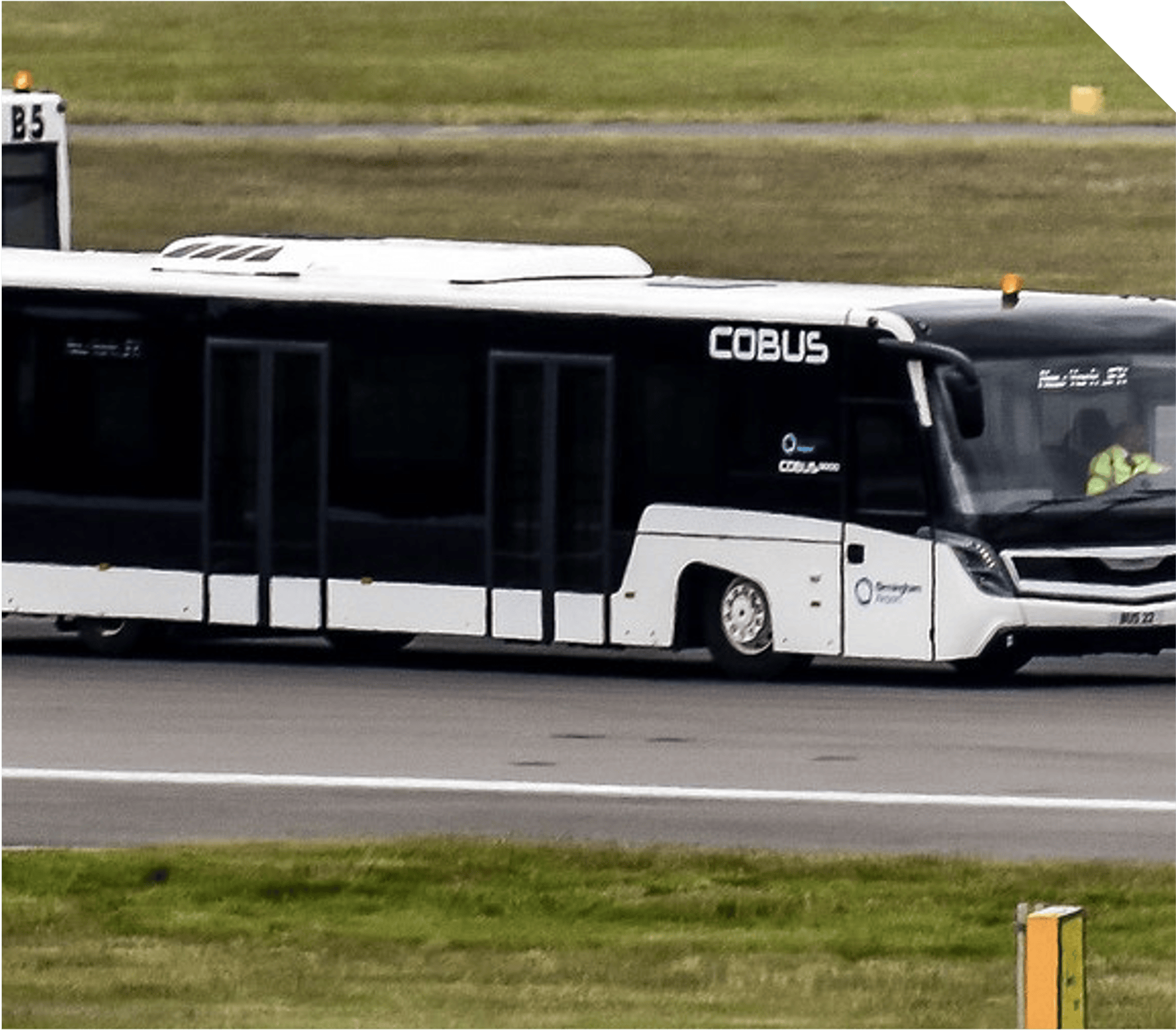

With a well understood forecast of passenger volume increase, the direct connection to the demand on both the airside and landside busing operation was to be defined. DC supported an initial program by:

- Analysing current performance data to gain insights to current process and performance losses, with process times identified for all key process steps & quick wins to gain performance improvements

- Conducting a significant number of process observation activities, physically on the bus with the drivers moving passengers around the airport as required and engaging with the drivers across all shifts to understand many of the frustrations & issues with the current process.

- Working alongside the SBDM & shift based BDM to gain their insights into the day to day challenges for the busing team.

- Reviewing of the current rostering process and data analysis to identify improvements in tools and planning aligned to demand.

- Defining daily performance metrics (KPI’s) to support daily performance reviews (visually based), and identifying coaching needs in basic problem solving & CI tools

As a result of the observations and analysis, a number of improvements were delivered:

- A Daily busing performance review – based on the safety of team, process, volume of journeys, issues encountered and utilisation of available resource for the day – included a basic level of actions and improvements required to reduce any performance risks.

- A detailed operational skills matrix for all PSO & BDM team, with identified skills gaps and agreed training plan.

- An bus asset review (Airside & Landside) to ensure spread of bus usage to allow for maximised life of the bus and to ensure appropriate servicing and maintenance.

- Analysis and process detail for SLA approval for all dispatching and gate handling agents and the Motor Transport team.

- A detailed bus journey demand data analysis including forecasted increase in that demand for 2024, to enable development of demand based rostering in readiness for the summer period.

- A Detailed next 6 months Continuous Improvements plan was developed, including further process improvements, Internal SLA’s, demand based rostering, skills development across the team, recruitment, and crew facility improvements.

Find Out More

Looking to enhance your airport operations, reduce queuing times and elevate the passenger experience? Our expertise in delivering complex projects within live operational environments ensures your airport remains compliant and focused on exceptional passenger service.

Contact our team to learn how we can support your next project.