Manufacturing

Defect Reduction and Process Optimisation

Defect Reduction and Process Optimisation

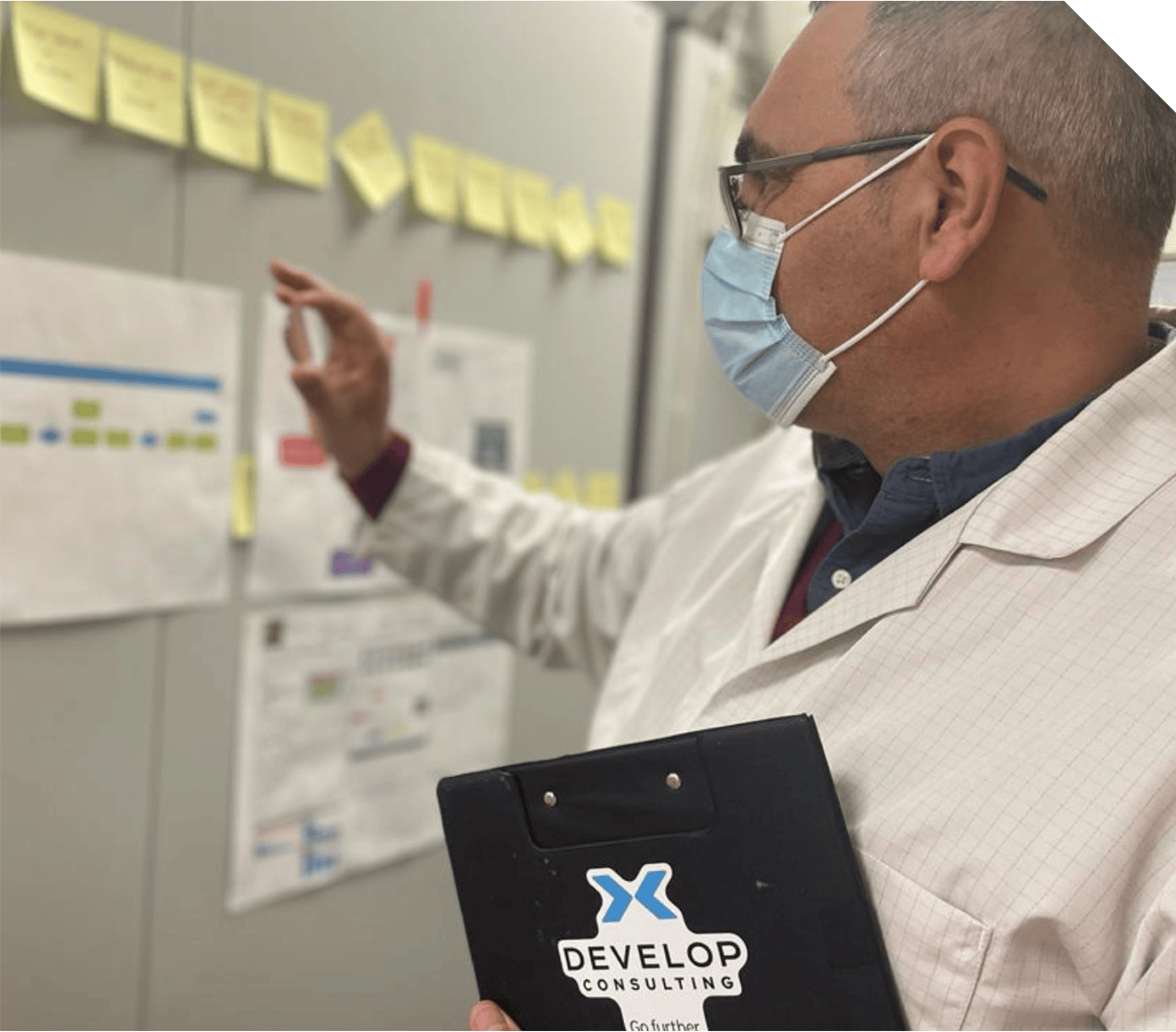

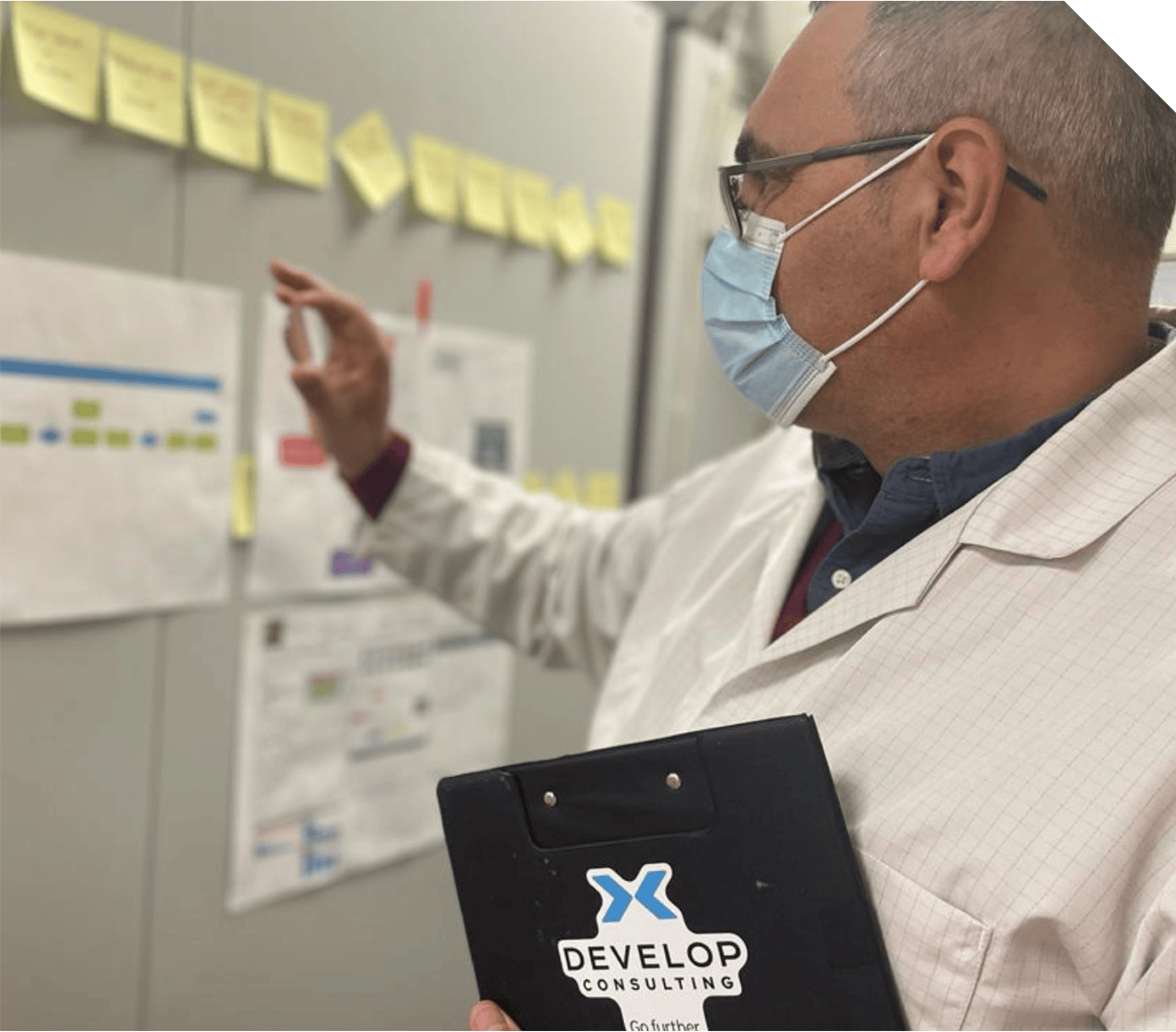

Develop Consulting significantly improved a UK lens manufacturer’s quality control and efficiency.

Our team was tasked with reviewing and then improving the client’s approach to identifying and solving quality defects, and improving the process flow.

Results

- 14 PPS projects opened and showing positive impacts on quality.

- 5% improvement in internal RFT score.

- A predicted 10% additional improvement at the close of all PPS projects.

- 50% of all processes now supported by SOPs.

- New and existing Operatives now being internally trained / audited by the Manufacturing Engineering Team in PPS and SOP writing.

Observations

Through interrogation of the clients existing quality data, we observed the that the glass manufacturing side of the business was only achieving a 72% Right First Time (RFT) throughput, with a scrap rate of 17%.

With the business struggling to engage and retain new resource, it was identified that by increasing the RFT, the requirement for additional resource could be significantly reduced.

The glass manufacturing department struggled to maintain a FIFO process, relying on one individual to move material between processes, with batches of lenses often then becoming late, resulting in lower levels of quality when trying to catch back.

Using a lean skills matrix, Develop Consulting assessed the Manufacturing Engineering Team and observed a lack of capability for structured Problem Solving.

Objectives

Develop Consulting were asked to review and then improve their approach to identifying and solving quality defects, and to improve the process flow.

Actions

We coached and mentored the production and engineering teams through:

- A 5S programme, taking the teams through the individual steps to ensure they understood this was not “just a good tidy up”, ensuring they grasped the fundamental process.

- The introduction of visual FIFO lanes, the material began to flow through in the required sequence, and no longer relied on one individual to move the batches forward.

- Practical Problem Solving techniques to raise the internal capability to identify and solve the root-causes affecting product quality.

- Developed a suite of Standard Operating Procedures, and coached the Production Engineers to author and update SOPs, with consideration to safety, quality and efficiency, and the sustainment of results achieved.