Manufacturing

Production Improvement

Production Improvement

We worked with the UK’s leading supply partner for innovative vehicular and pedestrian access control solutions.

They manufacture made-to-measure manual and automatic barriers, turnstiles, sliding gates, bi-folding gates and swing gates.

Results

- 10 week backlog of orders cleared in eight weeks

- 35% increase in Production output

- Reduced lead time from 10 weeks to 1 week

- Cost of Quality for missing Items reduced by 66%

- Re-use of duplicate materials, saving £78K

- Transparency of daily performance

- Robust two-week production plan in place – also used by sales team

- Transparency and improved reaction to issues

- An overall ROI on the investment of over 6:1

Observations

They were looking to grow their business, with the initial priority to create a robust, high performing operations team to allow the senior management to redirect their focus towards creating new products and services. The organisation structure had recently been redefined with some additional appointments.

Objectives

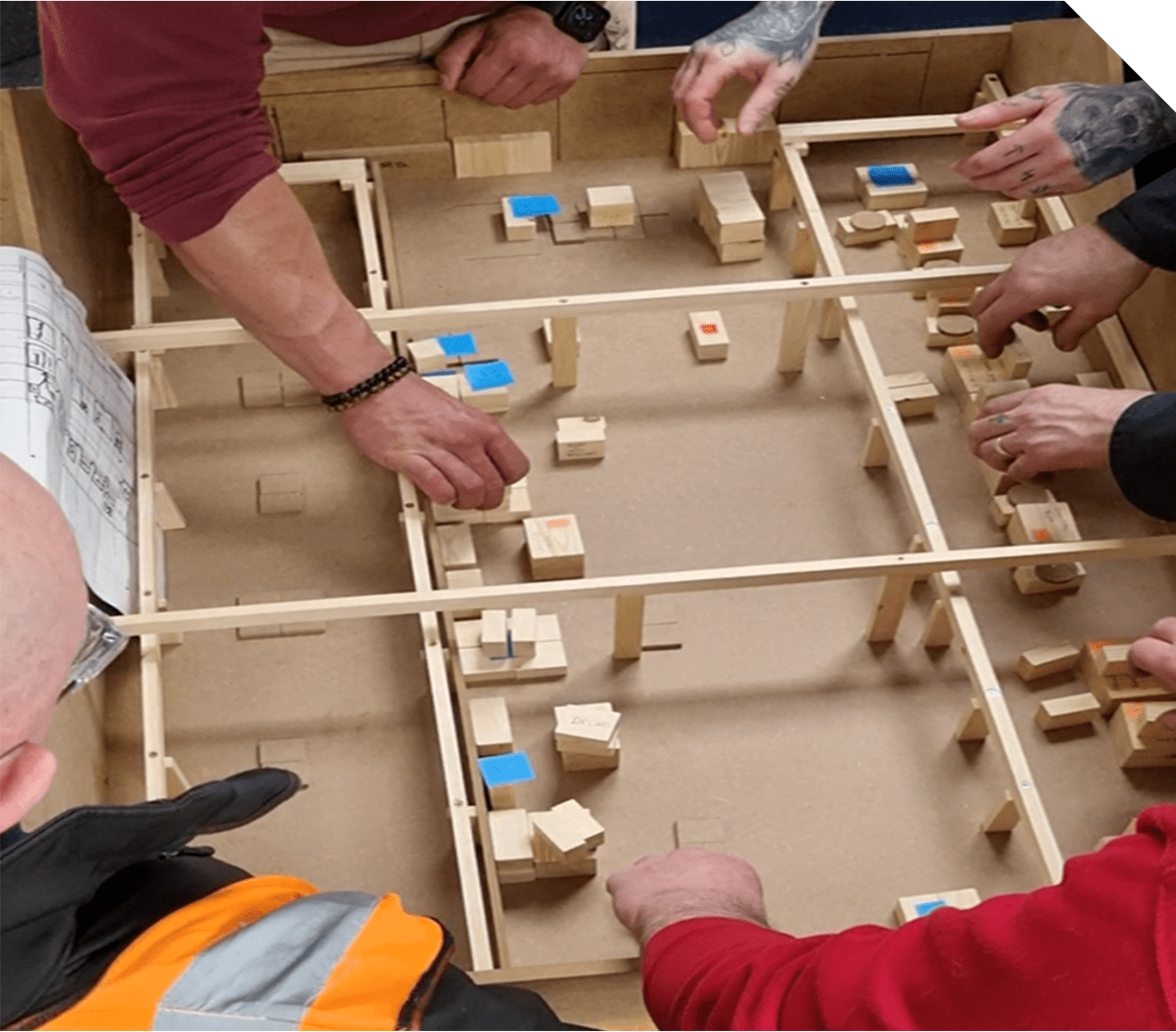

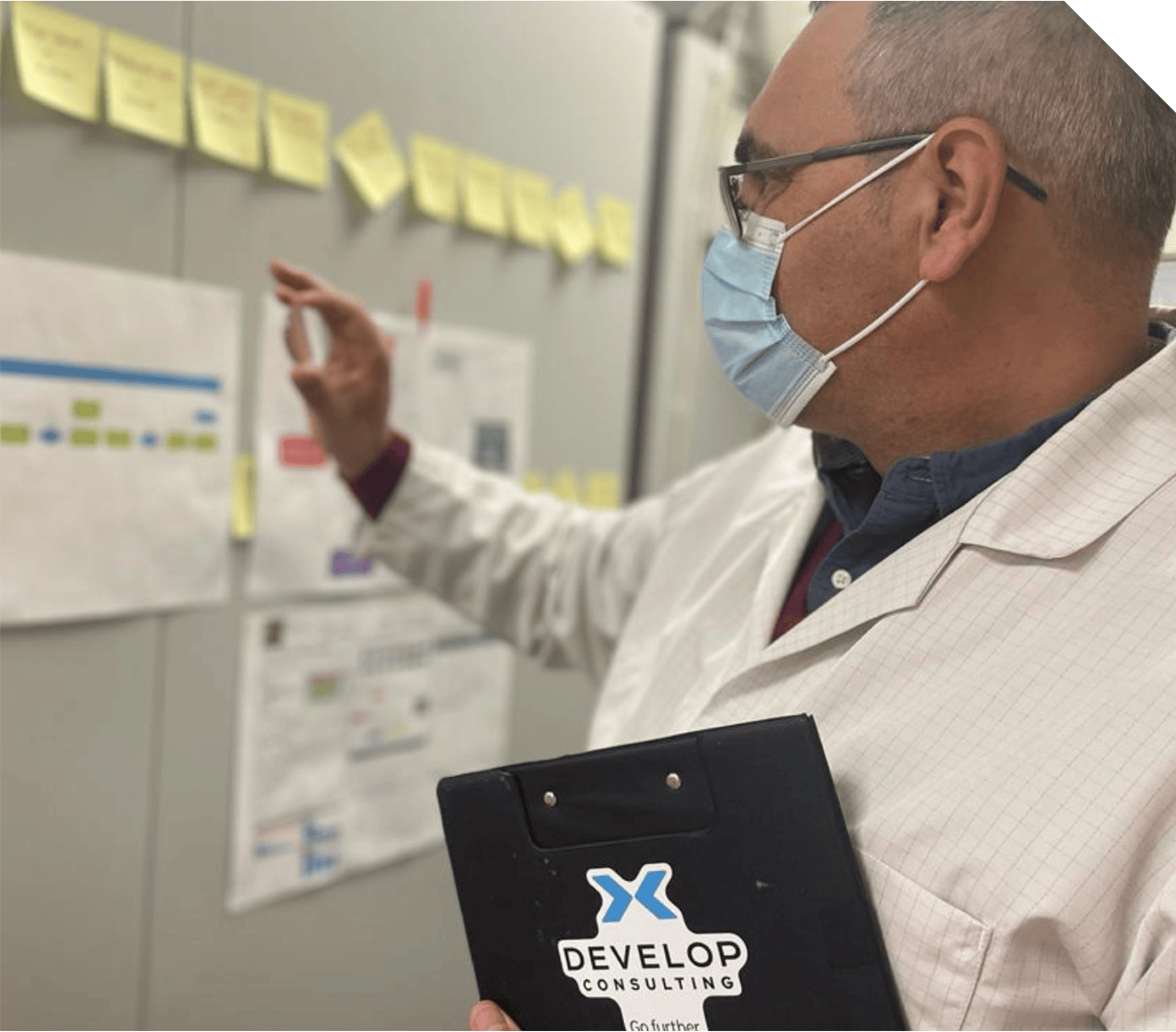

Develop Consulting were asked to improve the production performance and support with the development of the operations team, particularly the middle-level managers and supervisors, through a hands-on approach, ensuring the changes were embedded within the team.

Actions

By using a collaborative approach with the team, we introduced a series of tools to stabilise and control production, improve teamworking and introduced basic lean principles to the factory floor.