Manufacturing

Practical Problem Solving Implementation

Practical Problem Solving Implementation

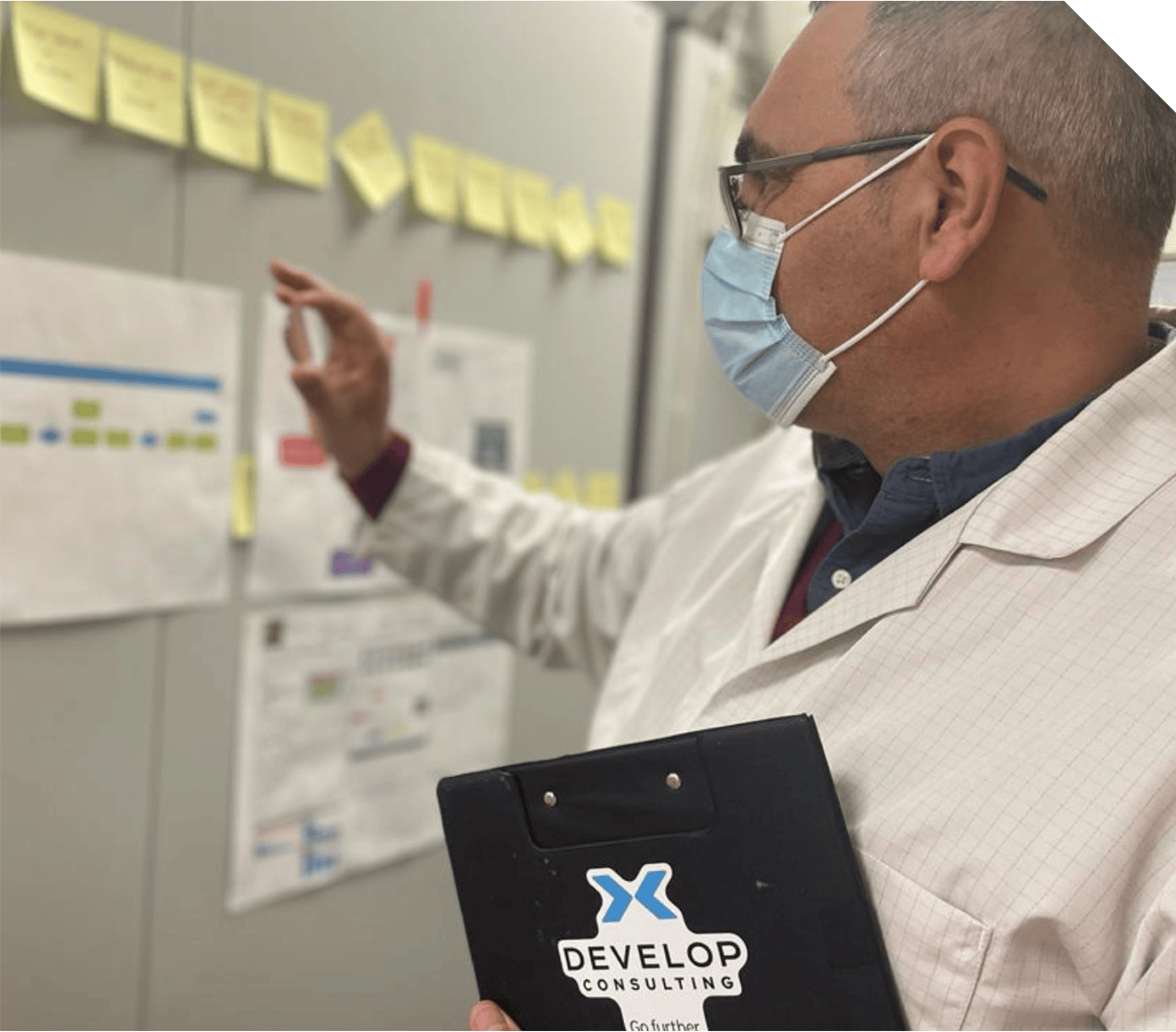

We worked with one of the leading aero engine, sub-assembly and fan blade builders, supporting their fan blade plant to reduce defects and issues through the implementation of Practical Problem Solving, whilst improving the organisation of the factory using the 5S methodology.

Results

- The top 5 process driven defects eliminated, reducing Defects Per Unit by 26%, with forecasted rework reductions saving £400,000 p.a.

- Slow moving Work-In-Process reduced by 50%.

- 10 Manufacturing Engineers coached in Practical Problem Solving.

- An “Exemplar” 5S cell set-up, for the client’s team to then replicate in other areas.

About the project

The client asked for our support to look at specific areas, including:

- Reducing slow moving WIP before impacting engine build

- Eliminating visual defects before “Super Polish” to prevent major rework having to be carried out

- Giving an internal team of engineers the tools to prioritise and eliminate the problems affecting their processes.

- Developing an exemplar 5S standard that can be replicated throughout the entire facility.

Improvement Actions

Develop Consulting interrogated the non-conformance database to understand which defects were causing the largest amount of concern.

Using Practical Problem Solving methodology, Develop Consulting coached a team consisting of operators, engineers and production leaders through the 8 PPS steps, identifying the true root causes and implementing robust, sustainable countermeasures to eliminate the top 5 defects. Following the successful reduction of these concerns, Develop Consulting continued to coach the original group as they led their own teams to tackle the next top five concerns in their respective areas.

Using Develop Consulting’s 5S training module and extensive 5S experience, the DC team trained and coached the Super Polish team to develop their department into an Exemplar production cell. Giving module training to underpin their understanding of 5S, the production team were able to assist with the roll out of 5S to the other cells.