With travel restrictions being eased, the Airport has been keen to ensure that all processes within the terminal were as slick and stress-free as possible, and with customers benefiting from the best experience possible while using the Airport.

Steve Clark, Manufacturing and Construction Director for the Lean and transformation business Develop Consulting, has been working alongside the team and Andrew Goodenough, Infrastructure Director at the Airport, on the project.

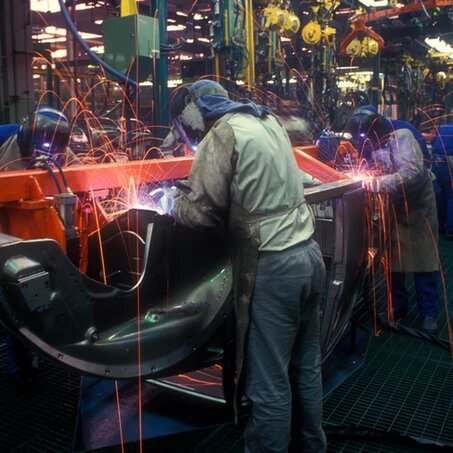

The Airport team has been given intense training in Lean methodology, which is a process which originated from the Toyota Production System (TPS) and follows the relentless pursuit of identifying and eliminating waste in all forms, including time and transport. The team were then coached to practically implement the skills to improve their projects.

Over 50 main areas of focus were identified through the project and Steve was also able to not only coach and advise the team, but also support in the development of a data dashboard to efficiently manage the airport on a day-to-day basis, along with improving project management. The dashboard allows the airport team to measure and assess the points more concisely, along with continuing to use their new skills in managing the site.

Steve said: “It has been a pleasure working with the team at Bristol Airport and it was great to be able to put some building blocks in place for when the customer numbers increase over the coming months and help them manage their airport on a daily basis much more effectively and efficiently. Our next steps are to roll out the Lean tools to the rest of the workforce from autumn onwards.