The Power of Lean Methodology – Unleashing Business Success

In today’s fast-paced and highly competitive business landscape, businesses are constantly seeking ways to improve efficiency, reduce waste, deliver customer value and drive sustainable growth.

One approach that has proven to be remarkably effective is Lean Thinking a methodology developed out of industry best practice and Toyota.

As the CEO of Develop Consulting and with a background rooted in the world-renowned Toyota Production System, I have witnessed first-hand the transformative power of Lean principles and been able to work with hundreds of teams across the world in sharing this methodology, helping to implement strategies and tools from the Board to the Shop floor and helping businesses to go further.

![]()

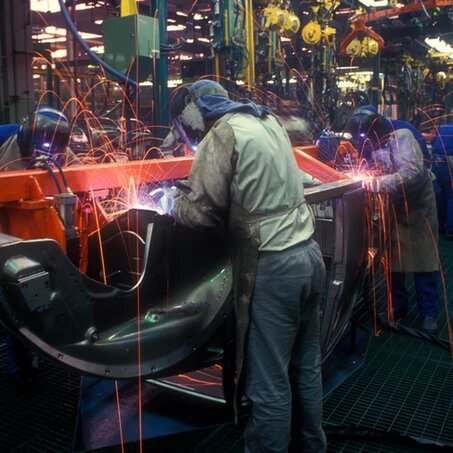

![]() At the heart of the Lean Methodology lies a philosophy of continuous improvement. Developed and perfected by Toyota, the Toyota Production System (TPS) set the stage for Lean’s emergence. I had the privilege of learning directly from Toyota, both in the UK plant set up and development but also as an employee in Japan experiencing their relentless pursuit of excellence and witnessing the tangible results it delivered. This experience shaped my belief in the power of Lean to create high-performing businesses through people and process.

At the heart of the Lean Methodology lies a philosophy of continuous improvement. Developed and perfected by Toyota, the Toyota Production System (TPS) set the stage for Lean’s emergence. I had the privilege of learning directly from Toyota, both in the UK plant set up and development but also as an employee in Japan experiencing their relentless pursuit of excellence and witnessing the tangible results it delivered. This experience shaped my belief in the power of Lean to create high-performing businesses through people and process.

Lean is not just a cost-cutting exercise or a one-time initiative. It is a comprehensive approach that encompasses processes, people, and culture. Lean is about streamlining operations, eliminating waste, and optimising value delivery to customers. It encourages a mindset of constant reflection and improvement. By engaging employees at all levels and empowering them to identify and solve problems, Lean fosters a culture of continuous learning and innovation.

The Pillars of Lean:

Value Creation: The foundation of Lean is understanding and delivering value from the customer’s perspective. By mapping the value stream and identifying non-value-added activities, organisations can focus their efforts on activities that directly contribute to customer satisfaction.

Eliminating Waste:

Lean strives to eliminate waste in all its forms. Whether it’s overproduction, excess inventory, waiting time, or unnecessary movement, Lean principles aim to streamline processes, reduce lead times, and optimise resource utilisation. It also considers management waste and setting clear direction and objectives a subject often overlooked.

Continuous Improvement:

The principle of Kaizen, or continuous improvement, is central to Lean. By encouraging small, incremental changes, organisations can make significant progress over time. Employee involvement and engagement are crucial for identifying improvement opportunities and implementing changes effectively.

Respect for People:

Lean recognises the value of every individual within an organisation. By creating a culture of respect, trust, and collaboration, organisations can tap into the collective knowledge and creativity of their employees. Empowering them to contribute ideas and be actively involved in decision-making processes leads to increased motivation and ownership.

The benefits of Lean and implementing and fostering a culture of continuous improvement are many from immediate benefits in SQCD (Safety, Quality, Cost & Delivery) to longer term sustainability, agility and business resilience. Implementing the Lean Methodology can yield numerous benefits for businesses:

> Enhanced efficiency and productivity through waste reduction.

> Improved quality and customer satisfaction.

> Increased profitability by optimising resource allocation.

> Enhanced employee engagement and empowerment.

> Greater agility and ability to adapt to changing market conditions.

Lean Methodology has stood the test of time and continues to deliver outstanding results for businesses across all industries.

As CEO of Develop Consulting, I have witnessed organisations transform their operations, achieve significant cost savings, and unleash their true potential through the adoption of Lean principles. By embracing a culture of continuous improvement, empowering employees, and focusing on delivering value to customers, businesses can position themselves for sustainable success in an ever-evolving marketplace.

Steve Boam

CEO Develop Consulting

To learn more about how Develop Consulting can support your business, visit this link.