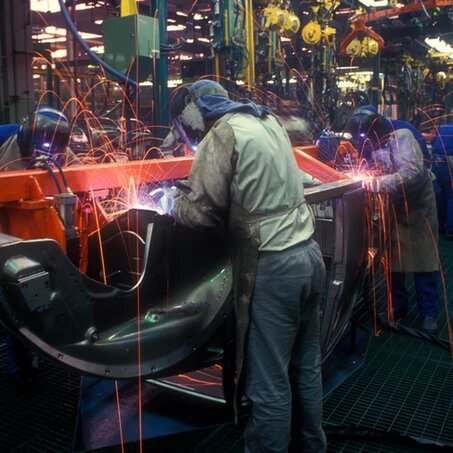

Lean methodology originated from the Toyota Production System (TPS) which revolutionised the manufacturing of goods back in the 1950s, also known as Just In Time (JIT) production. Toyota encouraged employees to be part of the production process, such as introducing quality circles which was a group of workers who meet to discuss improvements in the workplace.

Lean is the relentless pursuit of IDENTIFYING & ELIMINATING WASTE in all of its forms in order to improve business performance and customer satisfaction and supports organisational excellence. Waste is categorized into 8 wastes;