The reasons why a business wants to implement Lean can be for many different reasons, but typically, it is business pressures, from customer demands or cost reduction for example.

Here are some examples of the areas Lean can improve;

- Quality – Using problem-solving tools (root cause analysis) to improve RFT (Right First Time) to the customer and eliminating repeat quality issues that result in rework or scrap.

- Efficiency – There are multiple Lean tools that can improve business performance and maximise the utilisation of employees by maximising value-added work. Visual management is a powerful tool that can help to identify and discuss opportunities for improvement through the use of KPIs (Key Performance Indicators).

- Profit/cash flow – Increasing productivity, whilst reducing cost and waste.

- Flexibility – This can be how a business manages resource skills/training or reacting to customer requests/changes.

- Increase value-added activity – Minimising or removing waste from processes such as Motion, Over producing, Over-processing for example.

- Safety – Always the number 1 focus. Standardising processes and the use of 5S helps to ensure everyone is working in the most efficient and safest way.

Here are examples Lean can reduce/eliminate;

- Waste – Having the ability to recognise waste and look to eliminate or reduce it. This is classed as Non-Value Add.

- Lead times – Improving lead times to the customer through continuous improvement (Kaizen) activities. This can be measured by OTIF (On Time In Full).

- Inventory – High inventory levels is waste. Reducing inventory levels can save cost, time, space and improve safety. This can be improved by the use of a Kanban system.

- Costs – Increasing Value Added activities can reduce costs in many ways, for example; materials, people, less scrap and rework.

- Complaints – Using data and feedback to drive improvements to satisfy customers

Does Lean fit into different sectors?

Although Lean came from the auto industry sector, it can be applied to any organisation in any sector with little adaption;

- Manufacturing (e.g. Food & Beverage, Marine, Rail etc…)

- Government / Defence (e.g. Air Force, Navy, Tax Office)

- Office (e.g. Insurance, Banking)

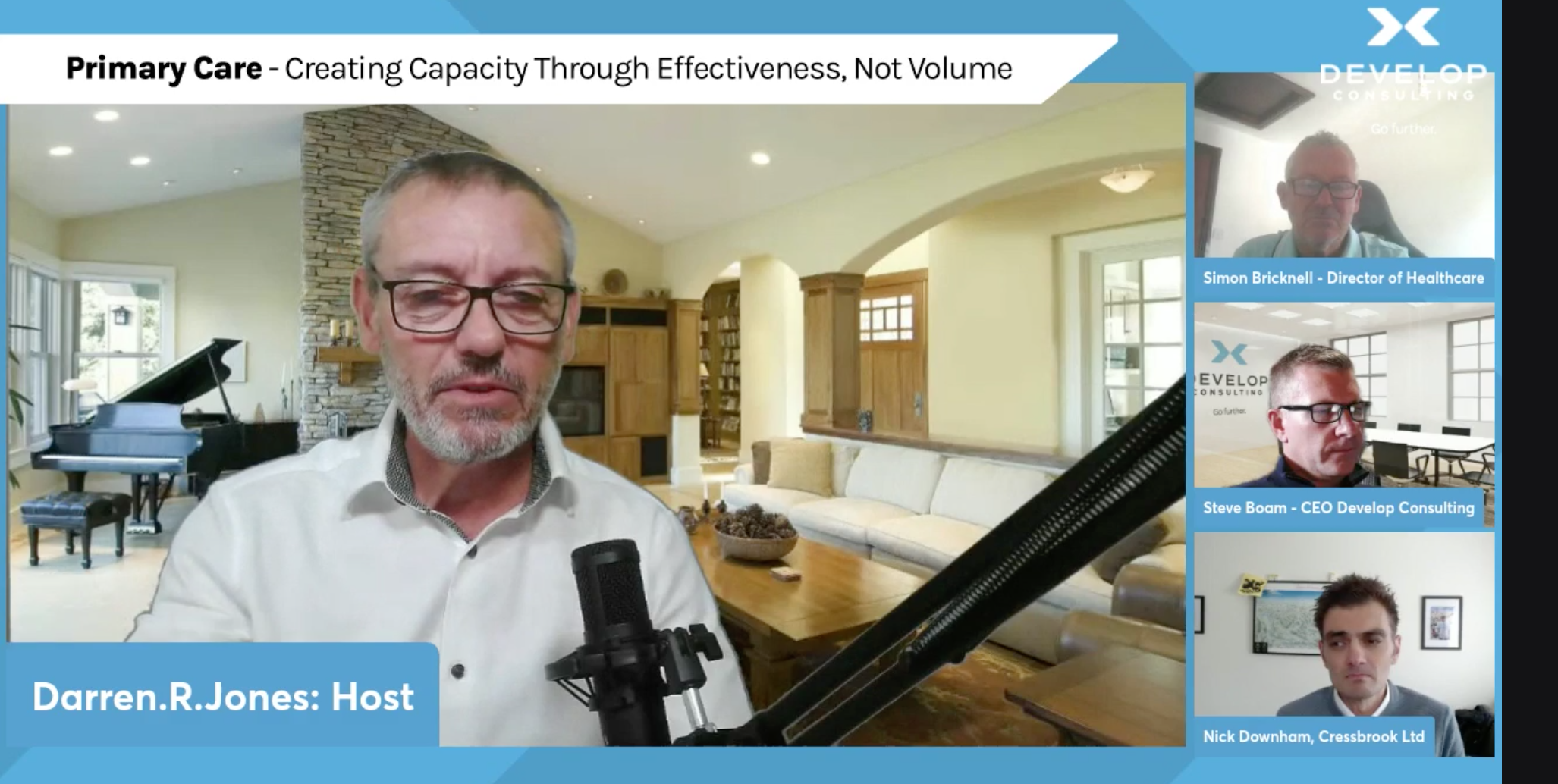

- Healthcare (e.g. Hospitals, Pathology, Pharmacy)

Leadership value, learning’s and Lean Principles can be transferred across all sectors…all have CUSTOMERS. Contact us today to find out how we can help your organisation.